This is somewhat standard practice in places like Iceland, where geothermal energy is being used on a massive scale. Even in southern Mondorf, hot water has already been located several hundred metres beneath the earth.

In this episode, host Olivier Catani speaks to geologists at the Bridges and Roads Authority, those in charge of measurements as well as the founders of a company specialising in repurposing lithium-ion batteries from e-bikes, cars, drills, and scooters.

RTL Today has teamed up with PISA, the Luxembourgish science magazine, to reproduce their original videos in English for our site. Watch all English videos on RTL Play, or discover the wide range of subjects previously covered in Luxembourgish here (there are 13 seasons, mind you! We’ll try and catch up).Our previous episodes covered the history of the tram, Luxembourg airport, explained how the coronavirus vaccine works, asked why traffic lights always seem to be red, investigated where our tap water comes from, looked at Luxembourg’s railways since 1859, took a dive into the Moselle Valley and its underground Dolomite mines, the history of Radio Luxembourg, the Constitution and more.

“Undertaking a project of this magnitude is unprecedented for the Geological Service. Luxembourg is on the brink of acquiring unique insights into its subsurface. Up until now, we’ve never known what exactly lies beneath our feet”, says Romain Meyer, Geologist at the Bridges and Roads Authority.

Meyer and his team are looking for warm water in Mondorf. The aim is to harness the natural heat within the earth as a source of renewable energy.

Lying at a depth of 730 metres is the bassin minier. The layer here is called the Buntsandstein layer (sandstone layers), which run up to 1,500 metres deep, if not deeper.

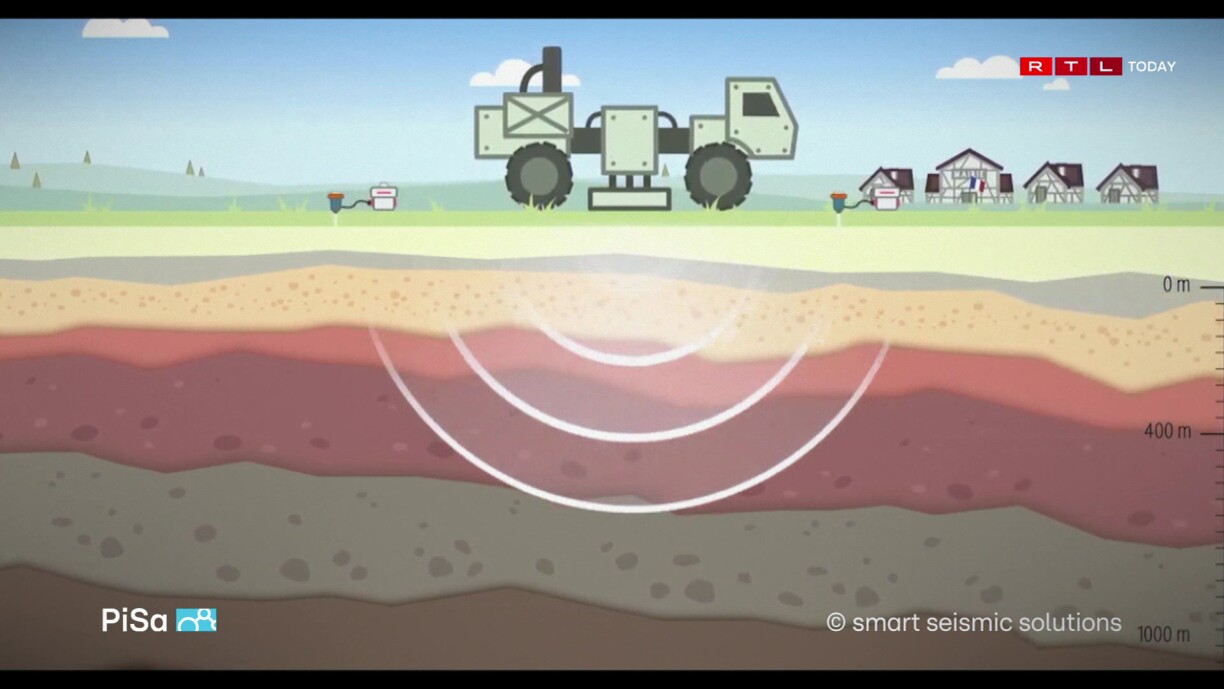

At a depth of around 1 kilometre, they expect 50 degrees, around 70-80 degrees at 2 kilometres. The objective is to identify the deepest layer capable of yielding the highest quantity of warm water. Lorries with special sensors send waves into the earth, with around 2,000 receivers on standby to capture the returning signals. These are then translated into something akin to an ultrasound image of the earth.

There is a possibility that the discovered water may not only offer heat but also contain lithium, much like the thermal water in Mondorf. Meyer says: “It’s plausible that there’s lithium in this water. The exact concentration remains unknown and will have to be determined at a later stage. However, given what other source indicators tell us, we can assume it’s substantial.”

Julien Wallendorff is in charge of measurements. “In real time, we’re monitoring vibration limits in accordance with a German standard that was verified at the start of the project. The people who operate these machines can halt the vibrations if we exceed these standards.”

Drilling is still a few years away, but earthquakes such as those recently experienced during geothermal projects in the Strasbourg area are not anticipated in Luxembourg.

Of course, lithium is not the only material that can be found in batteries. There is also cobalt, manganese, nickel, and graphite, which are sourced from far away places. What’s more, the working conditions in the places where they are mined are not always the best.

A Luxembourgish start-up based near Karlsruhe, in Kuppenheim to be precise, is developing machinery that aims to extend battery lifespan and simplify the recycling process.

Antoine Welter, one of the founders of Circu Li-on based in Hesperange since 2021 (but with production in southwest Germany), explains that the company chose to produce in Germany as more people are living in the area. As transporting old batteries across borders has become increasingly challenging, the company opted for Germany.

Circu Li-on specialises in repurposing lithium-ion batteries from e-bikes, cars, drills, and scooters. A battery pack consists of many cells. At Circu Li-on, they want to extend the overall battery life.

Tun Welter of the company breaks down the problem: “The big problem with these lithium ions, which are the very small cells in there that we have just seen, is that they all age in different ways. This means that if you have a battery containing 20 of these cells, as little as two malfunctioning cells can render the entire battery pack ineffective. By disassembling them, you can reuse the 18 functional cells in a new battery.”

“What happens nowadays is that they are all thrown into a huge shredder to be crushed and ultimately incinerated. That’s the solution the industry has nowadays.”

The company’s robots dismantle the batteries, separating plastic from metal and other recyclable materials. What remains are the bare cells. Leveraging their in-house diagnostics, the team can now discern the vitality of each cell, distinguishing the good from the faulty. Artificial Intelligence (AI) plays a big role in this process.

This automation not only saves time but also money. Recycling and upcycling become cheaper and, consequently, more appealing. Furthermore, the influx of rechargeable batteries in the future will render manual management impossible. Circu Li-on aims for expansion so that as many cells as possible can be recycled or given a second life.